Custom metal parts play an integral role in many industries, including automotive, aerospace, medical, and consumer goods. Machining alone may not fulfill all functional or aesthetic requirements in these fields; thus custom metal part finishing becomes crucial. We will examine its key aspects, the most popular techniques available today, and how you can select an effective process that meets your individual requirements in this article.

Custom Metal Part Finishing

Custom metal part finishing refers to post-production processes applied post-manufacturing that aim to enhance appearance, functionality, and durability of manufactured parts. Such techniques ensure parts meet stringent industry standards while withstanding environmental stresses; finishing may include polishing, coating, texturing or any other surface treatments designed to optimize metal properties.

Popular Metal Part Finishing Techniques

1. Anodizing

Anodizing creates a protective oxide layer on metal surfaces, typically aluminum, to increase corrosion resistance while adding aesthetic options through coloring options and aesthetic aesthetics.

2. Powder Coating

Powder coating involves creating a durable and high-quality finish using electrostatic spray deposition technology to apply an elegant yet protective finish that resists chipping, fading and scratching. It has become one of the most sought-after coating methods.

3. Electroplating

Electroplating deposits a thin coating of metal such as chrome or nickel onto the surface of an object to increase wear resistance, conductivity, and aesthetic appeal.

4. PVD Coating (Physical Vapor Deposition)

PVD coating provides an ultra-thin and hard coating with superior surface durability and modern aesthetic appeal, making it suitable for applications demanding both performance and aesthetics.

5. Polishing

Polishing smooths metal surfaces to increase their shine while decreasing friction. It is widely utilized by industries like medical devices and consumer electronics for its high-gloss effect.

6. Brushing

A brushed finish adds texture, concealing scratches while giving a sophisticated appearance - often used for decorative applications.

Why Finishing Matters for Custom Metal Parts

1. Improved Corrosion Resistance

Various finishing techniques, such as anodizing or powder coating, create a barrier against moisture, chemicals, and oxidation which reduces corrosion risk while prolonging product lifespan.

2. Improved Durability

Finishing processes increase surface hardness and resistance to wear, which reduces maintenance costs and ensures reliable performance.

3. Aesthetic Appeal

The perfect finish can make any metal part visually striking and customizable options are limitless when it comes to aesthetic appeal. From matte finishes to mirror-like surfaces, customization options abound.

4. Functional Upgrades

Finishes like electroplating enhance conductivity while texturing can increase grip or decrease friction for specific applications.

How to Select the Appropriate Custom Metal Part Finishing Process

Selecting the appropriate finishing process depends on several key considerations: Materials: Make sure the finishing technique you select complements your metal substrate - anodizing may work better on aluminum while PVD may suit stainless steel better.

Industry Requirements: Certain industries may require special finishes; for instance, medical devices often necessitate polished biocompatible surfaces.

Environment: When selecting a protective finish for an operating environment such as moisture exposure, temperature fluctuation or chemicals, consider your environment carefully to select an ideal protective coating solution. Budget: Some finishes such as powder coating are cost-effective while more sophisticated solutions such as PVD may require greater investment.

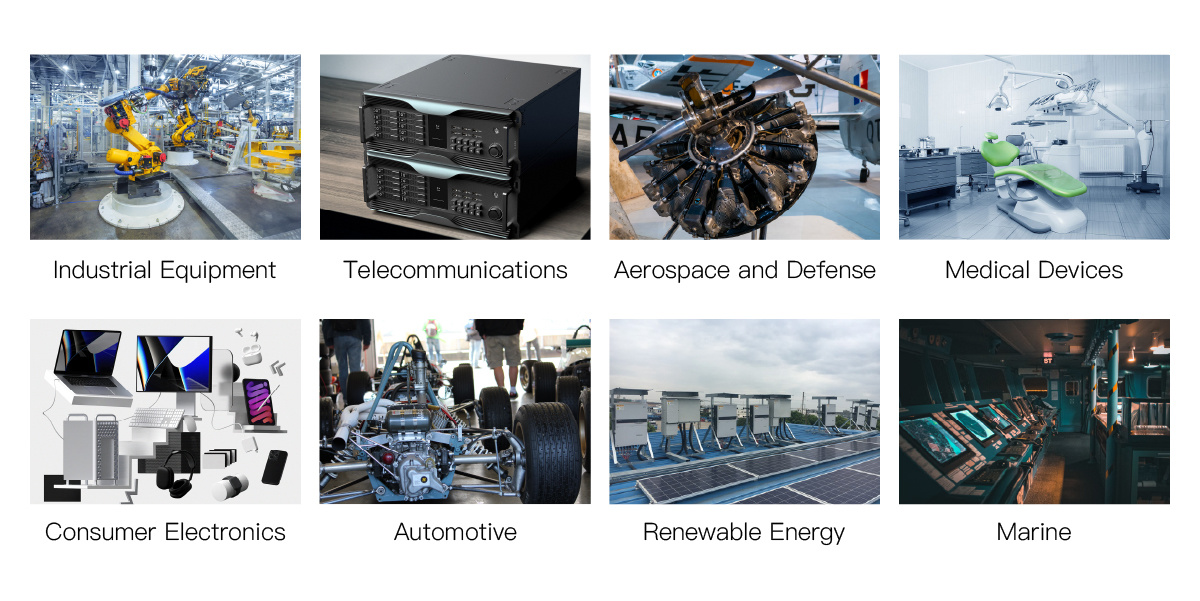

Applications of Custom Metal Part Finishing

1. Automotive Sector

From decorative trims to functional engine components, finishes such as electroplating and powder coating ensure both durability and style in this sector of industry.

2. Aerospace Industry

Lightweight and corrosion-resistant coatings are essential in parts exposed to high altitudes and extreme environments.

3. Medical Devices

Polished and biocompatible finishes enhance the usability and safety of surgical tools and implants, increasing their usability while simultaneously increasing safety.

4. Consumer Electronics

Brushed or anodized finishes offer a sleek aesthetic in devices like smartphones and laptops.

Future of Custom Metal Part Finishing Services

Advances in finishing technology such as eco-friendly coatings and 3D surface texturing have enabled more eco-friendly and sustainable solutions, giving manufacturers access to superior performance while simultaneously minimizing their environmental footprint.

Custom metal part finishing is an integral step in the production process, helping parts meet industry standards while meeting customer expectations. By understanding available techniques and their applications, manufacturers can ensure their products satisfy both standards and customers. No matter whether it's automotive, aerospace or consumer goods - having the appropriate finish can make a world of difference in performance, appearance and durability.

Comments on “Custom Metal Part Finishing: A Comprehensive Guide”